AFRRI Reactor Resumes Operations to Support Military Readiness

By Sarah Marshall

After six years of inactivity, the Uniformed Services University’s Armed Forces Radiobiology Research Institute (AFRRI) TRIGA, or Training, Research, Isotopes and General Atomics, reactor resumed operations on July 25, 2022. The reactor has been offline for upgrades to its instrumentation and control system.

The TRIGA is classified as a non-power reactor and does not produce electricity like a commercial nuclear power plant. The TRIGA reactor is designed to be inherently safe. By law, all reactors in the U.S. must have negative temperature feedback – wanting to slow down or stop the chain reaction as the fuel temperature increases. But what differentiates the TRIGA from power reactors is that it has 10 times the amount of negative temperature feedback. As the power increases, the reactor wants to shut itself down. Unlike power reactors that have to maintain active water cooling to prevent fuel from melting, even for a period after shutdown, TRIGA is designed to shut itself down and would naturally air cool at a temperature below that which would cause fuel damage. This unique feature makes it safe to house TRIGA reactors in many hospitals and university campuses throughout the U.S.AFRRI was established in 1961 to advance the understanding of the effects of ionizing radiation. Scientists conduct research in biodosimetry, combined injury (radiation plus conventional injuries), metal toxicity, low dose radiation, and the development of radiation countermeasures in three main areas: radiation protectants, radiation mitigators and radiation treatments. AFRRI research has also supported the development of cancer treatment in both the military and the general population by better understanding how to prolong bone marrow expectancy exposed to this type of radiation. This research directly supports operational military forces and is critical, should service members become exposed to radiation.

AFRRI’s TRIGA reactor is housed in a deep open pool of purified water, and can simulate the radiation emitted from the detonation of a nuclear weapon, from the prompt neutron and gamma radiation that is emitted within the first minute to the subsequent fallout radiation. Adjacent to the pool are two large exposure rooms. The radiation from the reactor flows into the rooms where biological specimens are located to study how radiation affects different specimens. The facility now uses a newly-revamped control room for the TRIGA, fully vetted and approved by the Nuclear Regulatory Commission, under the careful watch of highly trained, licensed operators.

In addition to the TRIGA reactor, AFRRI also has two cobalt-60 irradiators, a linear accelerator (LINAC), computed tomography scanner (CT) and small animal radiation research platform (SARRP) systems to support its military readiness research mission. The cobalt irradiators are capable of studying the effects of radiation on the entire specimen as a whole, while the LINAC and SARRP are capable of focusing the radiation into narrow beams to study the effects of radiation on specific areas of a specimen.

|

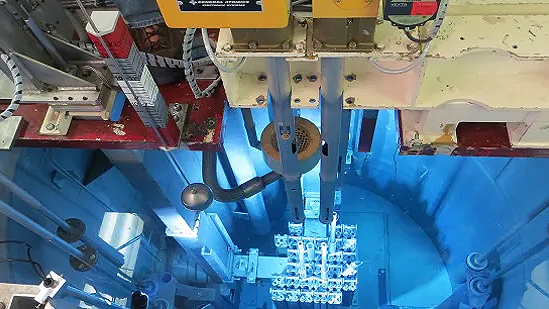

| A Training, Research, Isotopes, General Atomics - or TRIGA - research reactor at the Idaho National Laboratory, pictured here, is much like the one at AFRRI that was recently turned on after undergoing upgrades. (Idaho National Laboratory photo) |

In addition to the strict safety protocols required by the Nuclear Regulatory Commission, Department of Defense and other oversight agencies, AFRRI recently instituted its own robust safety conscious work environment (SCWE) program. The program is designed to promote open dialogue with employees on nuclear safety-related issues and is intended to ensure that all AFRRI personnel feel comfortable raising their concerns and that they will be assessed and mitigated.

“Our greatest priority, in addition to supporting the fight in a future nuclear contaminated battle space, is safety,” said Army Col. (Dr.) Mohammad Naeem, AFRRI’s director. “We go well above and beyond what is required. We have honed our skills to the level where excellence is no longer an option. It’s a habit.”